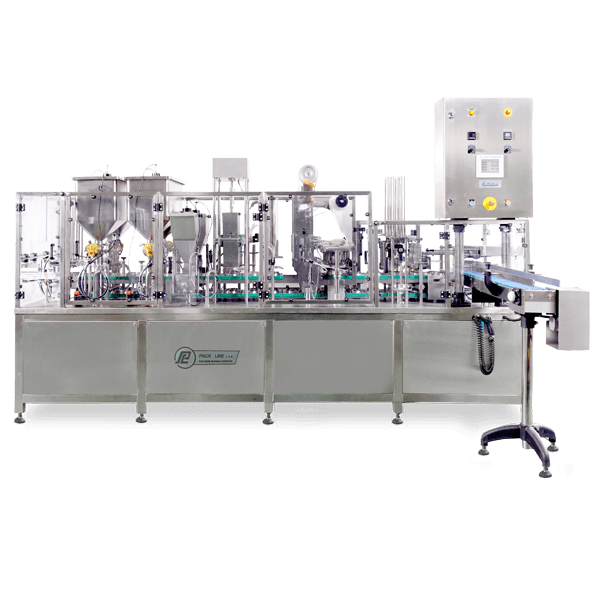

PXM

Fully Automatic, Servo-driven, Linear Filling, Sealing and Capping Machine

Output: 80 – 300 units per minute

Product: Powder / Granulated / Pieces / Paste / Additional

PXM is a fully automatic, in-line filling and sealing machine that is based on digital, mechanical and pneumatic assemblies. This automatic packing machine is suitable for packaging a wide range of liquid, paste, granulated and powdered products into preformed containers of various size and shapes. The machine can be used for dairy products, salads, dressings, desserts, dry soups, frozen dishes, cosmetics and much more.

PXG

Pneumatic Driven, Fully Automatic Filling, Sealing and Capping of Pre-formed Containers

Output: : 25 to 100 cups per minute

Product: Powder / Granulated / Pieces / Paste / Additional

Extremely versatile, PXG machines feature fully automatic filling, sealing and capping operations. With PXG´s flexibility, you get the best application to perfectly match your packaging needs.

Fillers can be fitted with a CIP cleaning system. Pre-cut lid or membrane cut from roll can be combined with a plastic cap. PLC control system regulates machine function in its entirety or through individual components. Machine adjustments to different container shapes and sizes are fast and easy

NBM

Output 30 to 120 units a minute

Product: : Powder / Granulated / Pieces / Paste / Liquid

NBM cup filling and sealing is a technologically advanced line of fully automatic rotary filling and sealing machines. This line, which features a smooth index or driven movement of a 12-position rotary platform, is the best the solution for liquid, paste, granulated and powdered products.

The main advantage of the NBM cup filling and sealing machine line is extreme flexibility.

NBM-70

Output 25 to 50 units per minute

Product: : NBM-70 A Paste / Liquid

NBM-70 B Powder / Granulated / Pieces

A fully automatic machine for filling and sealing of cups with pre-formed lids or membrane cut directly from roll. Rotary platform is driven by analogue engine. The machine easily handles up to 20 ounces of volume and utilizes seven- to nine-station rotation platforms depending on cup configuration and capacity. Two filling operations may be preformed in the same cup before sealing. The entire process is automatic with most operations performed pneumatically.

PAO

Packaging Equipment for Catering,

Semi-prepared Foods and Different Prepared Dishes

Product: 10 to 120 units per minute

The PAO semi-automatic machine uses film to hermetically seal the packaging of products. The lid is cut from the film roll, conforming with the container’s shape. Different laminated films, used with or without printing, are oriented by the photo mark. The packaging process uses plastic containers of various sizes and shapes. Product packaging may include modified atmosphere, with the previous vacuum draw-down. The PAO is available in semi-automatic or automatic-sealing modes and as

complete packaging lines for semi-prepared foods and prepared dishes.

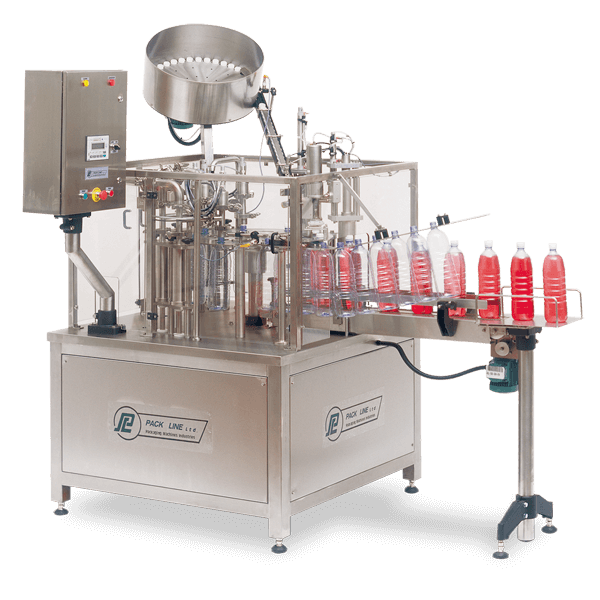

PFM

Output: : Up to 10 Filling Heads

Product: : Liquid / Paste

PFM is a rotary bottling machine line designed with a mechanical rotary platform and pneumatic assemblies. It’s the best solution for bottling and capping mineral water, beverage, juice, salad dressings washing detergents and many other products. Extreme flexibility is the machine’s greatest asset.

The PFM can operate with up to four fillers for liquid and paste products. Machine adjustments for different bottle and cap shapes is fast and easy

PLF-5S

Pneumatic Driven, Fully Automatic Filling, Sealing and Capping of Pre-formed Containers

Output: : Up to 10 Filling Heads

Product: : Liquid / Paste

The PLF-5S offers forming and cutting membranes from a roll instead of pre-cut aluminum foil lids. The machine easily handles a variety of products up to a volume of 20 ounces. Most operations are performed pneumatically. The machine includes: cup feeding and ejection assemblies, lid feeding and sealing assemblies, filling unit, rotary platform and PLC control system. Pre-formed cup filling and sealing adjustments to different container sizes are fast and easy. Options include: set for different cups, shapes and size coding device, discharge conveyor, rotary table for final assembly, additional heads for different products, gas flashing system, and safety guard.

PLF-2000

Pneumatic Driven, Fully Automatic Filling, Sealing and Capping of Pre-formed Containers

Output: : Up to 10 Filling Heads

Product: : Liquid / Paste

The machine is designed on a mechanical platform base combined with pneumatic assemblies. The PFM is a great solution for bottling and capping water, beverages, juices, salad dressings, washing detergents and lots more. The machine features up to two or more fillers for liquid and paste products and is adjustable to different bottle, jug and cap shapes.

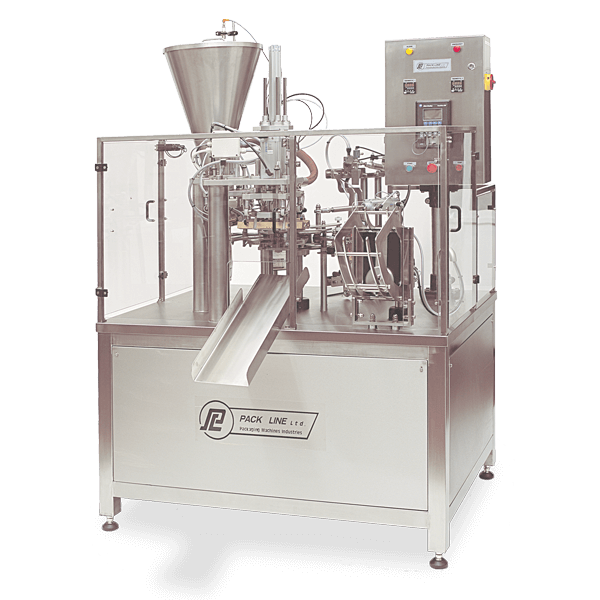

PD

PDP-2M Output :Up to 20 pouches per minute

PDP-4 Output : 35 to 40 pouches per minute

Product: : Powder / Granulated / Pieces / Paste / Liquid

PDP-2M and PDP-4 are designed on a mechanical rotary platform base with pneumatic assemblies. Extreme flexibility are the machines’ greatest asset. The machines include rotary platform, pouch dispenser and ejector, room for two fill sealing and cooling bars.

Also included are hot stamp coding device, PLC control system and safety guarding.